Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

![]() June 13, 2022

June 13, 2022

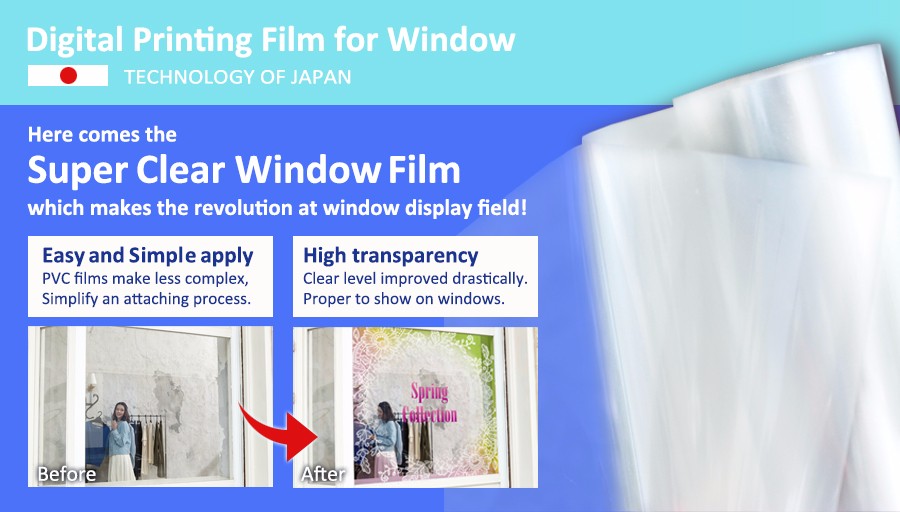

Ultra-transparent glass stickers use a fully transparent material, called ultra-permeable membrane, also known as PVC ultra-permeable membrane, the main component is polyvinyl chloride, and other components are added to enhance its heat resistance, toughness, ductility, etc.At present, in the advertising industry, ultra-transparent UV glass stickers can be said to be the most widely used products.

What is UV ultra-transparent glass sticker?

UV ultra-transparent glass stickers use a fully transparent material, called ultra-permeable film, also known as PVC ultra-permeable membrane, the main component is polyvinyl chloride, and other components are added to enhance its heat resistance, toughness, ductility, etc.

At the same time, this material is flexible, easy to form, not brittle, non-toxic and non-polluting, and has a long storage time. The reason why it is called UV ultra-permeable film is because the picture is printed by UV inkjet printing, and UV printing can achieve one-time white color. And color spray painting, transparent film (frosted sticker, transparent film, PVC Film, etc.) white bottom color printing, color white color double-sided color color printing, increase the color brilliance, make the pattern more three-dimensional. UV color printing simplifies the process, the effect is more beautiful, and it is resistant to fading.

What is the installation steps of UV ultra-transparent glass paste

At the same time, there are also some problems, such as: the product has warped edges, the screen is fogged and blistered, and the residual glue is difficult to handle after tearing off. In addition to the reasons for using inferior products, the use of glass stickers also causes these problems. key.

So, what are the correct installation steps?

1. Before construction and paste, clean the glass window with water to check whether the glass surface is clean and tidy;

2. Spray clean water evenly on the glass window during construction, paste the product in place, and then gently scrape with a scraper to remove clean water and air bubbles;

3. When the glass sticker is torn off for construction, it is recommended that the product and the glass to be pasted form a 90-degree angle, and tear off evenly.

Features of UV ultra-transparent glass paste products:

1. The UV ultra-transparent glass stickers achieve the effect of double-sided pictures through the output method of UV machine "color and white color";

2. The UV super-transparent glass paste is a super-permeable film that passes through water. It is equipped with a PET bottom with extremely high surface flatness, and the transparency of the paste glass is excellent;

3. The UV super-transparent glass paste is removable and super-transparent, and the glue can be removed after one year.

Precautions for using UV ultra-transparent glass stickers

1. When the UV ultra-transparent glass is attached to the output screen using UV equipment, it is recommended to use UV soft ink. Usually roll-to-roll UV printing equipment is equipped with UV soft ink. When using neutral or hard UV ink to output the screen, It will cause product brittleness, so it is not recommended to use flat UV or roll UV machine to output images;

2. When the UV ultra-transparent glass is pasted on the glass, pay attention to cleaning the surface:

a. When the UV ultra-transparent glass is attached to the wet paste, only water must be used, and other alkaline substances such as detergents are not allowed, otherwise distortion will occur.

b. When the UV ultra-transparent glass is attached to the wet paste construction, the initial adhesion is very low. Pay attention to protect the screen. Generally, the adhesion will return to normal after 12 hours.

c. Special attention should be paid to "blue wave" and "anti-ultraviolet glass". The surface of these glass is coated, which is prone to the phenomenon of poor sticking.

The above is the sharing of GIGI, I hope it will help you!

The above is the Application scope and precautions of UV ultra-transparent glass stickers we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.